-

Automated Warehousing System

-

Warehouse Equipment Systems

-

Warehouse Software Systems

-

Food Packaging Machines

-

Robotic Automation Integration

-

Chemical Packaging Machine

-

Industrial Automation Machinery

-

Machine Vision Sensors

-

Industrial Electrical Spare Parts

-

Automatic Food Processing Machine

-

Cold Chain Warehouse

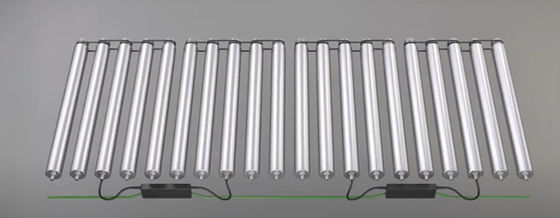

3000mm Length Intelligent Roller Conveyor Connect With CTU Or AMR For Warehousing System

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Applications | Suitable For Carton, Box, Jumbo Bags Etc | Machine Structure | Stainless Steel # 304 |

|---|---|---|---|

| Product Dimension | 3000*600*750mm | Roller Informaiton | With Intelligent Electric Roller + Non-motorized Roller , Ø50*500mm |

| Electric Roller | Combine With Brushless Gear Reduction Motor And Other Parts | Drive Type | 1 Electric Roller Drive 5pcs (front -end) +5pcs(after-end) Non-motorized Roller |

| Speed | 0-40m/min Adjustable, By Frequency Control | Power Supply | 220V/50Hz |

| Covering Machine | AGV, CTU And AMR, Etc | ||

| Highlight | Intelligent Roller Conveyor,3000mm Length Roller Conveyor,Warehousing System Roller Conveyor |

||

3000mm Length Intelligent Roller Conveyor With Electric Roller To Connect With CTU Or AMR For Warehousing System

| Application | Suitable for carton, box, jumbo bags etc | |

| Machine Structure | Stainless Steel # 304 | |

| Product Dimension | 3000*600*750mm | |

| Roller Informaiton | With intelligent electric roller + non-motorized roller , Ø50*500mm | |

| Electric roller | Combine with brushless gear reduction motor and other parts | |

| Drive type | 1 electric roller drive 5pcs (front -end) +5pcs(after-end) non-motorized roller | |

| Speed | 0-40m/min adjustable, by frequency control | |

| Power Supply | 220V/50Hz | |

| Covering Equipment | AGV, CTU and AMR, etc | |

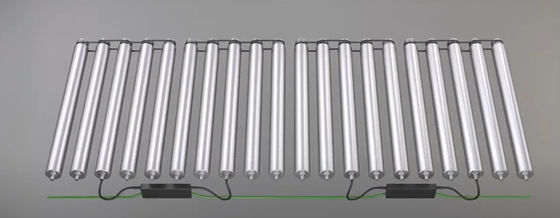

A new type of roller conveyor support frame installtion

![]()

* Change tradtional square tube supporting legs to bending sheet metal parts;

* All these bending metal parts are drilled with a row of holes, to match different height;

* When manual installtion, the workers can adjust the holes at same height, so as to install the conveyor.