-

Automated Warehousing System

-

Warehouse Equipment Systems

-

Warehouse Software Systems

-

Food Packaging Machines

-

Robotic Automation Integration

-

Chemical Packaging Machine

-

Industrial Automation Machinery

-

Machine Vision Sensors

-

Industrial Electrical Spare Parts

-

Automatic Food Processing Machine

-

Cold Chain Warehouse

Max 45m Automated Storage Retrieval System AS-RS Stacker For Max 1500kg Pallet

| Place of Origin | China |

|---|---|

| Brand Name | CLX |

| Certification | N/A |

| Model Number | CLX-HLoad-1.5T |

| Minimum Order Quantity | 1 |

| Price | $50000-100000 |

| Packaging Details | Export Standard plywood case pack; |

| Delivery Time | 30-40 days |

| Payment Terms | T/T, L/C, D/A, D/P, OA,Western Union, MoneyGram |

| Supply Ability | 30PCS/month, 400pcs/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Dimension(mm) | Non-standard As Request | Stacking Height(m) | 0-16m |

|---|---|---|---|

| Max Load/carton | 1500kg | Straight Speed | 0-100m/min |

| Acceleration | 0-2.5m/s2 | Column | With Endurable Steel Structure |

| Ground Rail | With Endurable Steel Structure | Drive Mode | Servo Motor Drive, With Endurable Belt |

| Cross Beam | With Endurable Steel Structure | Straight Accuracy | ±5mm |

| Lifting Accuracy | ±3mm | Fork Accuracy | ±2mm |

| Safety 1 | Appearance Detection | Safety 2 | Over Weight Detection |

| Safety 3 | Cord Loosen Detection | Safety 4 | Cord Broken Detection |

| Safety 5 | Speed Limit, And Avid Falling Device | ||

| Highlight | Automated Storage Retrieval System AS-RS,Automated Storage Retrieval System Stacker,1500kg Pallet Asrs Systems |

||

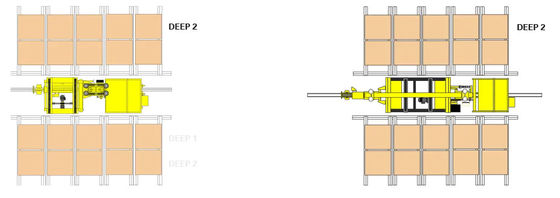

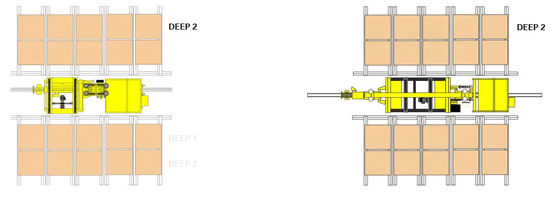

AS-RS Stacker ( Automated Storage and Retrieval System Stacker) For Max 1500kg Pallet For Max 45m European Standard Automated Storage & Retrieval

The Automated Storage and Retrieval System (AS-RS) is a new type of modern warehouse that is mainly composed of high-lifting shelves and track tunnel stackers, combined with different kinds of warehouse equipments, to achieve automatic storage and cargo management.

Track tunnel stacker refers to a stacker that travels on ground rails. This type of stacker consists of three key parts: steel ground rails, columns with steel wheels, and forks. The column with steel wheels runs back and forth on the steel rail, and the cargo fork runs up and down on the column. The structure of the steel rail, column, and cargo fork is similar to a three-axis motion platform.

At present, the commonly used tunnel stackers are all ground supported stackers. The metal structure columns of this stacker mainly consider the bending strength in the track plane. Therefore, it is necessary to increase the moment of inertia of the columns in the walking direction section. Due to the fact that the driving devices of the ground supported stacker are all installed on the lower crossbeam, which is easy to maintain and repair, sensors for automatic control can also be installed on the ground, making it convenient to use.

FEATURE

1. Based on XYZ 3-Axis structure, drving system, navigation functions, with AMR function extensibility;

2. For pallet packed products load/unload;

3. Pallet pack max capacity ≦1.5 ton, we suggest pallet capacity 0.5-1.5 ton;

4. We suggest shelves height 10-25mm;

5. The load/unload speed is determined by the motion speed of X/Y axis, X/Y travel length and operating time;

6. WCS: with WCS, for better warehouse management;

7. Intelligence: can work with ERP, WMS, for whole factory intelligent management.

TECHNICAL PARAMETERS

| Heavy-duty AS-RS Stacker for Pallet or Carton | |

| Model # | CLX-HLoad-1.5T |

| Structure | With top rail, ground rail, Uppe crosbeam, lower crossbeam and standing Column, and customized fork gripper; |

| X-Axis | Customized as design, with endurable steel on top rail and ground rail |

| Y- Axis | Customized as design, with endurable steel column; |

| Z-Axis | Customized fork gripper |

| Stacker height | Customized as buyer's request; |

| Horizontal Travel Speed | 0-180 m/min |

| Horizontal Acceleration | 0-0.5m/s2 |

| Horizontal travel accuracy | ±5mm |

| Lifting speed | 0-60 m/min |

| Lifting Acceleration | 0-1.0m/s2 |

| Lifing accuracy | ±3mm |

| Control System | PLC Contorl system on AS-RS Stacker, with WMS on whole AS-RS |

| Carton Griper | With customized Carton Griper and Carton Basket |

| Griper length | Adjustable at two type, single and Doube Griper |

| Max pallet/pack Weight | 1500kg |

| Weight range | 0.5 - 1.5 ton |

| Safety 1 | With pack detection device, over sized and weighed carton reject |

| Safety 2 | Belt loose or broken can be detected and alarmed |

| Safety 3 | Speed limit and fall prevention |

| Elevator | Recycled structure, used to transport pack downwards |

![]()

Transition Rail for Stacker

![]()

![]()

![]()

![]()