-

Automated Warehousing System

-

Warehouse Equipment Systems

-

Warehouse Software Systems

-

Food Packaging Machines

-

Robotic Automation Integration

-

Chemical Packaging Machine

-

Industrial Automation Machinery

-

Machine Vision Sensors

-

Industrial Electrical Spare Parts

-

Automatic Food Processing Machine

-

Cold Chain Warehouse

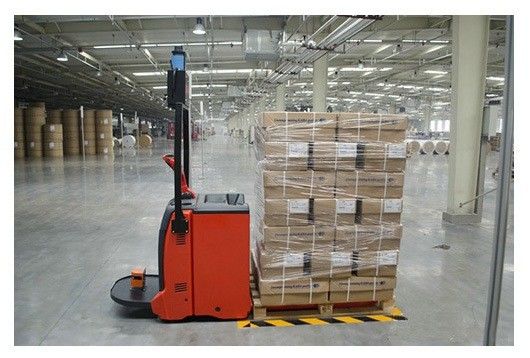

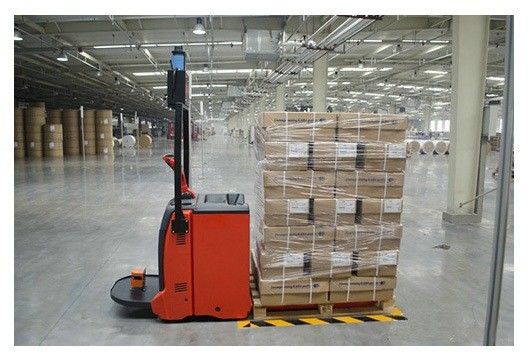

Pallet Transfer And Stacker AGV Automated Warehousing System Loading Capacity 1200kg

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Pallet Transfer And Stacker AGV | Product Dimension | L2295*W900*H2100mm, Or Customized |

|---|---|---|---|

| Navigation Methods | Laser/magnetic Navigation | Lifting Height | 2700mm, Or Cusotmized As Your Request |

| Communication Type | 5G/WIFI | Running Direction | Forward/Backward/straight And Curve/left And Right Division |

| Running Speed | 90m/min | Parking Accuracy | ±10mm |

| Positioning Accracy | ±10mm | Scalability | High |

| Maintenance | Regular Maintenance On Forklift | Loading Capacity | 1200kg |

| Highlight | 1200kg Automated Warehousing System,Stacker AGV Automated Warehousing System,Pallet Transfer Fully Automated Warehouse System |

||

Great Lifting Function PALLET Transfer And Stacker AGV Automated Warehousing System For Loading Capacity 1200kg

Pallet forklift AGV, with a load capacity of 800-2000KG, navigation positioning accuracy ±5mm, can take the place of traditional forklifts functionally, meanwhile, this pallet forklift AGV, with compact size and smart operation, can be widely used to the handle of various standard pallets.

These pallet forklift AGVs, can achieve running automatically by WIFI or 5G network, with integrated navigation methods such as Beidou, 3D multi line laser radar, and inertial navigation, be suitable for outdoor logistics distribution between workshops and factories, two modes like manual drive and auto drive can be selected, lithium battery as power supply, 24 hours working can be avaliable.

FEATURE

The pallet forklift AGV adopts a steering wheel system, which has a simple structure, reliable use, small turning radius, suitable for single-sided pallets, high driving force, good vehicle stability, and high cost-effectiveness; European standard and non-standard vehicle models can also be customized as buyer's requests.Technical Parameters:

| Model | CLX-C2-CL12 | |||||||

| Type | Pallet transfer and stacker forklift AGV | |||||||

| Product Dimension | L2295*W900*H2100mm, or can be customized | |||||||

| Capacity | 100-1200KG, or can be customized | |||||||

| Navigation methods | Laser/magnetic navigation | |||||||

| Lifting height | 2700mm, for pallet transfer type | |||||||

| Communication Type | 5G/WIFI | |||||||

| Running Direction | Forward/Backward/straight and curve/left and right division | |||||||

| Running Speed | 90m/min | |||||||

| Parking Accuracy | ±10mm | |||||||

| Positioning Accracy | ±10mm | |||||||

| Working time | 24 hours | |||||||

| climb ability | ≤8% | |||||||

| Turning radius | ≤1.8m | |||||||

| Battery Capacity | Suitable for 8 hours working,can be customized with more capacity | |||||||

| Charging type | Manual Charging/Auto Charging/Change battery | |||||||

| Safty sensor area | with in 3m, brake distance can be within 20mm; | |||||||

| Alarming type | Dual alarm with voice play and warning light | |||||||

| Safty protection | Front obstacle detection sensor, mechanical anti-collision mechanism dual protection and emergency stop button | |||||||

Applications:

Customization:

Support and Services:

We are committed to providing excellent technical support and services for our Automated Warehousing System (AWS). Our team of professionals is always available to help you with any questions and concerns you may have.

We provide the following technical support and services:

- Installation and setup of the automated warehousing system

- Configuration and customization of the system to meet your specific needs

- Troubleshooting and maintenance of the system

- Updates and upgrades to the system

- On-site training and support

- Online support and resources

Our team is available 24/7 to answer any questions or concerns you may have. If you need assistance, please contact us at info@changlianxin.com

We look forward to providing you with the best technical support and services for your automated warehousing system.